Revolutionary product >> The savior of hard material tapping >> Tungsten steel milling cutter >> Suitable for stainless steel, pre-hardened steel or materials with hardness up to HRC62°

At present, when tapping screw holes on hard materials, especially heat-treated plates, discharge tapping is mostly used. The processing time of one hole is about 30 to 40 minutes. It is not only time-consuming, but also costly. The quality of the processed screw holes is very high. The opening is too loose and the bottom of the hole is too tight. Although traditional milling cutters are used for fast processing, the cost per piece is high and the lifespan is short. Moreover, many manufacturers do not provide NC codes, making it difficult to get started. After years of research and development, our company not only The unit price is low, it also has chamfering function, and has a longer service life. It only takes 2 to 4 minutes to process one hole. Moreover, each tool comes with the NC code exclusively developed by our company, which already contains drilling and milling programs and the speed. In addition to the short program and high compatibility with the feed amount, it can easily handle whether it is single hole processing or multi-hole processing.

Through innovative design, ordinary steel is used as the main body, and the blade is made of special tungsten steel, which greatly reduces the price. The end of the blade uses a directional chip elimination angle, which is different from traditional milling cutters that cannot perform chip elimination processing. The old machine can still process with ease. Using traditional cutting fluid can achieve 10 times the service life. Through physical processing tests, the service life of each tooth cutter can reach 50-100 holes (tested with material SKD11, hardness HRC60°, M10 milling 10 teeth). If the processed object is white iron (stainless steel), the processing life can reach more than 2000 holes.

Each tool comes with multiple modes of programs to choose from, and are written in NC code using macro instructions. If the screw thread is too loose or too tight during processing, you can directly change the parameters using common variables, and the machine will automatically change the program. And continue processing without starting from scratch, and there is no need to convert NC code, which greatly saves development time.

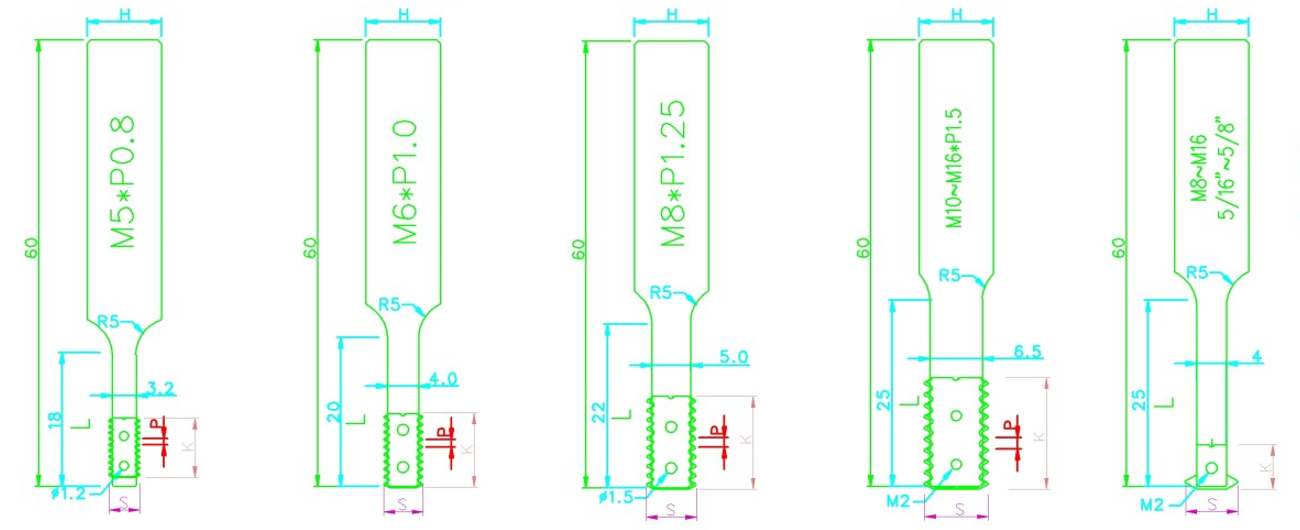

| Item no. | Code | (P)Pitch | Number of the Cutter's pitches |

Cutting diameter |

(H)Shank diameter | (S)Blade diameter | (L)Length | (K)Blade Length | Maxinum threads milled | Chamfering function | Drilling function | Threading milling time |

Maximum holes threaded (HRC60°) | Maximum holes threaded (HRC30°) | Price |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 01 | M5 | 0.8 | 10 | 4.2~4.4 | ø10 | ø4.2 | 18 | 8 | 22 | — | — | 3min | 50 | 1000 | |

| 02 | M6 | 1 | 10 | 5.2~5.4 | ø10 | ø5.44 | 20 | 10 | 20 | 有 | 有 | 3min | 60 | 1000 | |

| 03 | M8 | 1.25 | 10 | 6.8~7.1 | ø10 | ø6.7 | 22 | 12.5 | 18 | 有 | 有 | 3min | 80 | 1000 | |

| 04 | M10~M16 | 1.5 | 10 | 8.5~9.0 | ø10 | ø8.6 | 25 | 15 | 17 | 有 | 有 | 3min | 150 | 1000 | |

| 05 | M12 | 1.75 | 8 | 10.2~11 | ø10 | ø8.6 | 25 | 17.5 | 14 | 有 | 有 | 4min | 100 | 1000 | |

| 06 | 1/4" | 1.27 | 8 | 5.1~5.3 | ø10 | ø5.2 | 18 | 10 | 14 | 有 | 有 | 4min | 40 | 800 | |

| 07 | 5/16" | 1.411 | 9 | 6.5~6.9 | ø10 | ø6.8 | 22 | 12.5 | 15 | 有 | 有 | 4min | 70 | 800 | |

| 08 | 3/8" | 1.588 | 9 | 7.9~8.3 | ø10 | ø8.0 | 25 | 15 | 15 | 有 | 有 | 4min | 140 | 800 | |

| 09 | Universal M8~M12 5/16"~7/16" |

1.25~1.8 | 1 | — | ø10 | ø7.1 | 25 | 6 | — | — | — | — | — | 200 | |

| 10 | Universal M10~M22 3/8"~5/8" |

1.25~2.5 | 1 | — | ø10 | ø7.1 | 25 | 6 | — | — | — | — | — | — |

Please link to the following website: www.durable99-milling.com.tw Select the specifications of the milling cutter you purchased to obtain the processing NC code. Customized special specifications are also accepted, please call us for enquiry.

The NC code developed by our company is tailor-made for the tools in the above table and is not suitable for imitating traditional dental milling cutters.

**Currently, this product has obtained invention patents from many countries. Please do not copy, manufacture or sell it privately**

Forward Enterprise Co., Ltd. Mobile: 0935-483795, TEL: 04-7368760~1, FAX: 04-7368767